Air-cooled Type

HOME > Product > Refrigerated air dryer > Air-cooled Type > Composite heat sink seriesComposite heat sink series

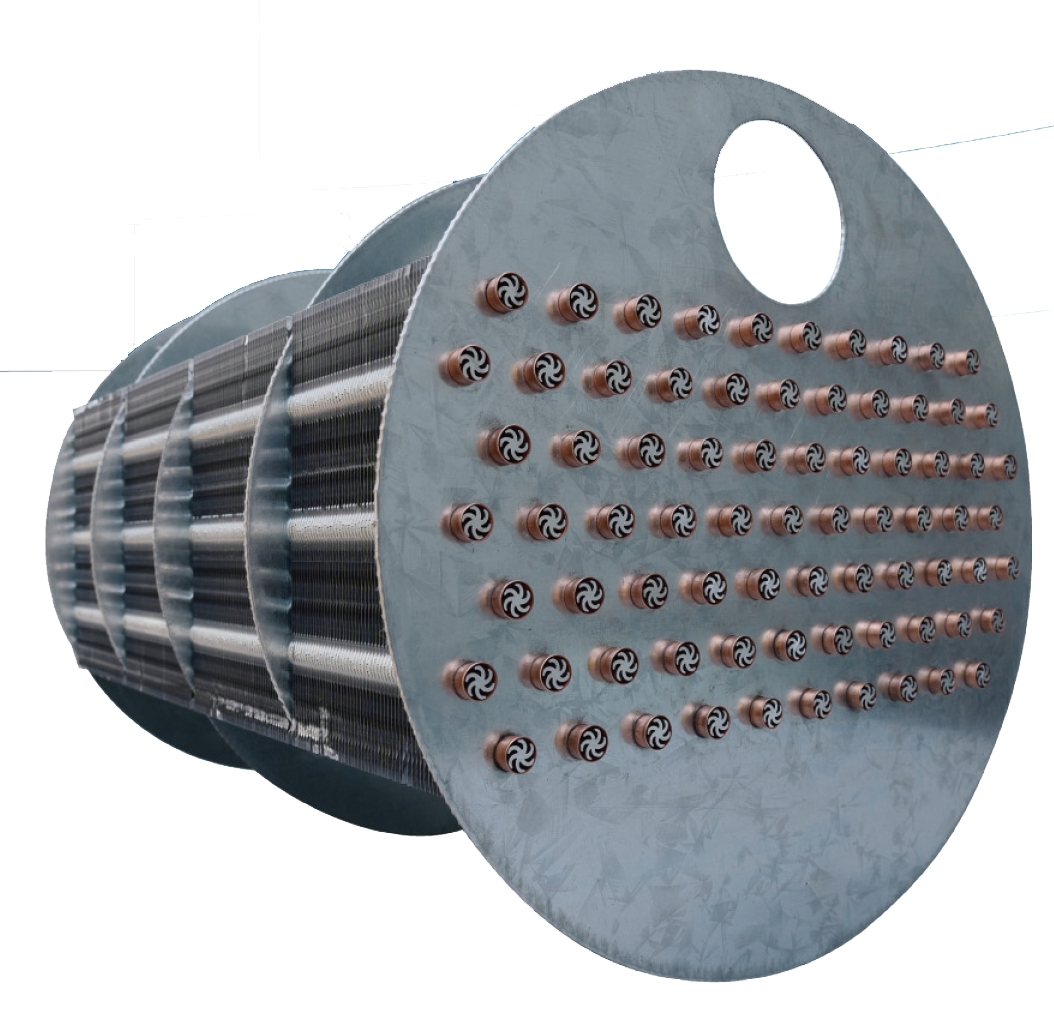

High temperature type air cooled models, Condensers and air coolers combine design, Small size, easy to install, easy maintenance, Applicable air compressor 1 ~ 50HP.

Two-stage counter and turbulent flow + fin-tube enhanced heat conduction patented technology. Especially be suitable for heavy load and high temperature environment.

|

|

1) Two-stage counter and turbulent flow.

In the heat exchanger, the high-temperature air entering from the environment will exchange heat with the cold air that has flowed through the evaporator. There are also many guide plates in the middle, so that the cold and hot air flows in a "counter-flow" and "turbulent flow" way to enhance the heat exchange effect.

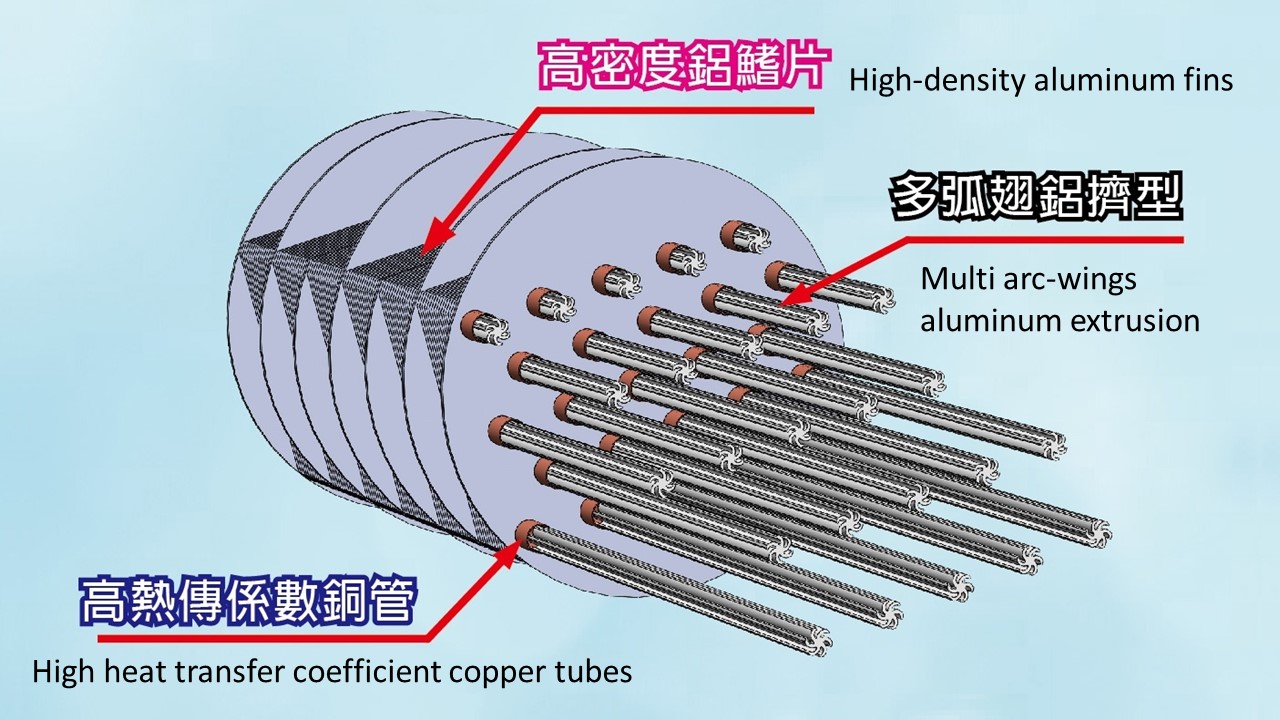

2) Multi arc-wings aluminum extrusion

The materials of the heat exchanger are all high heat-conduction coefficient, including high-density aluminum fins, high heat transfer coefficient coppers, and the other key innovation-- Multi arc-wings aluminum extrusion. The aluminum extrusion is placed in the copper tube, which can force the air to diverge and fully contact the copper tube. The aluminum extrusion can also transfer heat to the copper tube, increasing the heat exchange efficiency by 20%.

The promotion of heat exchange efficiency can bring more convenience and possibility.

1) Overcome the limitation of environment temperature

First, the heat exchange efficiency becomes better, which means that the allowable inlet hot air temperature can be increased, and it can be used in a higher temperature environment. Currently, the applicable ambient temperature of our product can reach 45°C.

2) Reduce purchase and use costs

When the outlet hot air can release more heat from the heat exchanger, the temperature entering the evaporator can be lowered so that it can reduce the load of the refrigerant compressor and reduce power consumption. Additionally, when the temperature of the hot air outlet decreases, it means that the same freezing capacity can process more flow of air. The processing capacity increase more 10% than before, so that the dryers can match the modern energy-saving and high-efficiency air compressors , and there is no need to buy a larger model. In this way, it can be helpful in terms of purchase, space utilization, electricity bills, and the maintenance costs in the future.

3) Maintain the factory environment

The dry cooling air from the outlet of the evaporator, gets more temperature rise after passing through the enhanced heat exchanger, which increases the outlet temperature by 7°C compared to the previous machines. Therefore, the outlet is less dew condensation, and it can reduce corrosion to avoid pollute the factory environment.

The unique technology-- "specific gravity laminar flow separation method".

Using the different physical properties of the fluid (air, water) and the design of pipe diameter , the Reynolds number in the pipe becomes a laminar flow state at low flow rate and does not mix with each other to achieve the best separation effect of condensed water and dry air.

![]()

Patented technology "dew point control protection" + perfect protection measures

|

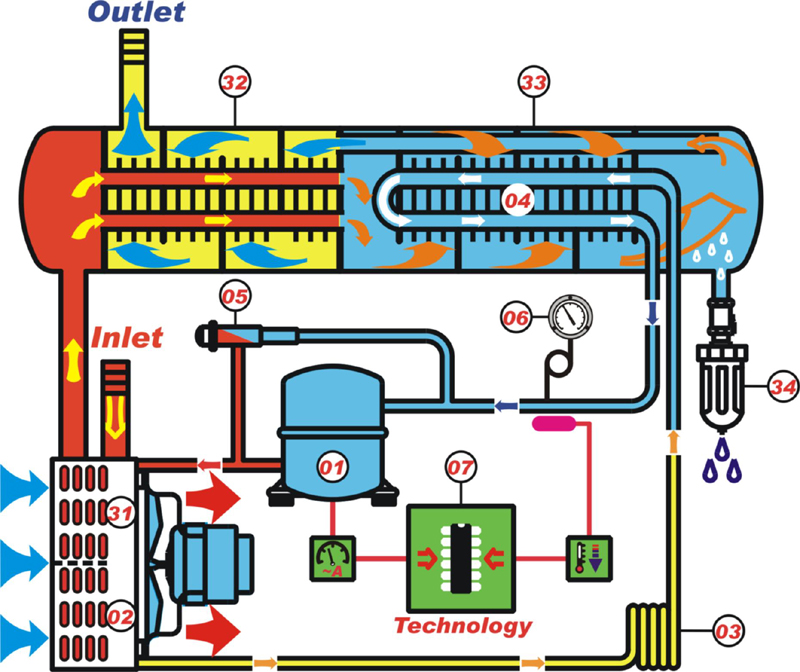

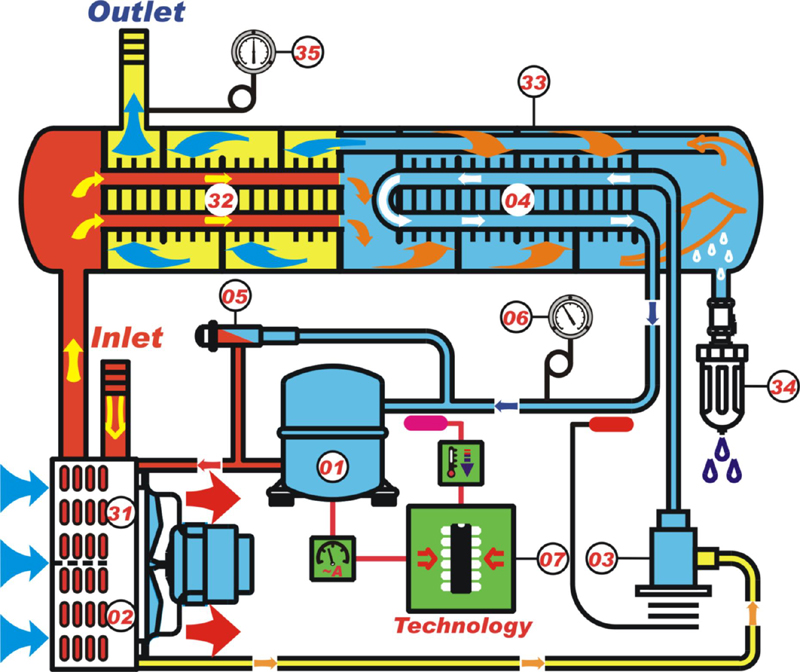

SD-005~SD-020 System flow chart

|

||

|

Refrigeration systems

|

|

|

Code

|

Name

|

|

|

01

|

Refrigerant compressors

|

|

|

02

|

Condenser

|

|

|

03

|

Capillary

|

|

|

04

|

Evaporator

|

|

|

05

|

Hot gas bypass valve

|

|

|

06

|

Low pressure gauge

|

|

|

07

|

Intelligent control and protection board

|

|

|

Air system

|

||

|

Code

|

Name

|

|

|

31

|

FrontCoolers

|

|

|

Ambient air VS Compressed air

|

||

|

32

|

Precooler

|

|

|

Compressed air VS Compressed air

|

||

|

33

|

Evaporator

|

|

|

Refrigerant VS Compressed air

|

||

|

34

|

Automatic drainage

|

|

|

SD-030~SD-060 System flow chart

|

||

|

Refrigeration systems

|

|

|

Code

|

Name

|

|

|

01

|

Refrigerant compressors

|

|

|

02

|

Condenser

|

|

|

03

|

Capillary

|

|

|

04

|

Evaporator

|

|

|

05

|

Hot gas bypass valve

|

|

|

06

|

Low pressure gauge

|

|

|

07

|

Intelligent control and protection board

|

|

|

Air system

|

||

|

Code

|

Name

|

|

|

31

|

FrontCoolers

|

|

|

Ambient air VS Compressed air

|

||

|

32

|

Precooler

|

|

|

Compressed air VS Compressed air

|

||

|

33

|

Evaporator

|

|

|

Refrigerant VS Compressed air

|

||

|

34

|

Automatic drainage

|

|

|

35

|

Outlet pressure gauge

|

|

Product Specifications

|

Model

|

SD-005

|

SD-010

|

SD-015

|

SD-020

|

SD-030

|

SD-040

|

SD-050

|

SD-060

|

||

|

Air flow capacity (Nm³/min)

|

0.6~0.8

|

1.2~1.6

|

1.8~2.3

|

2.4~3.1

|

3.6~4.7

|

4.2~5.5

|

6.0~7.8

|

6.5~8.5

|

||

|

Scope of use

|

Pressure dew point (℃)

|

2~10 ℃

|

||||||||

|

Inlet temperature (℃)

|

5~80 ℃

|

|||||||||

|

Ambient temperature(℃)

|

5~45 ℃

|

|||||||||

|

Inlet pressure (㎏/㎝²G)

|

2~10 ㎏/㎝²G『Optional customized 10~16 ㎏/㎝²G Model+【H1】』

|

|||||||||

|

Power supply frequency

|

1ψ220V/50~60Hz『Optional customized 1ψ380V、440V、460V / 50~60Hz』

|

|||||||||

|

Running current (A)

|

2.3

|

2.8

|

3.2

|

3.6

|

5.5

|

7.0

|

8.5

|

11.0

|

||

|

Power consumption (kW)

|

0.31

|

0.48

|

0.58

|

0.63

|

0.91

|

1.12

|

1.33

|

1.51

|

||

|

Refrigerant

|

R-134a

|

R-22『Optional customized R407C』

|

||||||||

|

Refrigerant control

|

Capillary

|

Automatic temperature expansion valve

|

||||||||

|

Capacity adjustment

|

Hot gas bypass valve+Condenser fan control

|

|||||||||

|

Protection device

|

Intelligent control and protection board+Compressor Overload Relay

|

|||||||||

|

Port size

|

½"

|

¾"

|

1"

|

1"

|

1½"

|

1½"

|

2"

|

2"

|

||

|

Dimensions (mm)

|

Length

Width

Height

|

600

400

570

|

650

400

650

|

700

400

770

|

750

400

870

|

950

470

930

|

950

470

930

|

1150

480

1020

|

1150

480

1020

|

|

|

Weight (kg)

|

47

|

55

|

64

|

74

|

117

|

122

|

152

|

160

|

||

|

Rated conditions

|

◎Inlet pressure:7㎏/㎝²G ◎Ambient temperature:45℃

◎Inlet temperature:60 ℃ ◎Pressure dew point:5 ℃

※(Other conditions to be corrected)

|

|||||||||

|

Inlet pressure (㎏/㎝²G)

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

Correction facto

|

0.40

|

0.55

|

0.69

|

0.81

|

0.91

|

1

|

1.07

|

1.13

|

1.17

|

|

Ambient temperature (℃)

|

30

|

32

|

35

|

38

|

40

|

42

|

45

|

|

Correction factor

|

1.10

|

1.09

|

1.06

|

1.03

|

1

|

0.94

|

0.88

|

|

Inlet temperature (℃)

|

55

|

60

|

65

|

70

|

75

|

80

|

|

Correction factor

|

1.08

|

1

|

0.93

|

0.87

|

0.80

|

0.73

|

|

Pressure dew point (℃)

|

2

|

5

|

10

|

|

Correction facto

|

1

|

1.1

|

1.2

|

Select [Air flow capacity] ≧ [Flow correction] models