NEWS

HOME > NewsThe heat exchanger performance promotion of air dryer. Patented technology: enhanced heat conduction

Date: 2021-03-01 < The heat exchanger performance promotion of air dryer.

Patented technology: enhanced heat conduction fin-tube heat exchanger >

Zhou Sheng is dedicated to research and produce the Refrigerated Air Dryer to meet the needs of the industry. Our air dryers which combine the patented technology -- enhanced heat conduction fin-tube heat exchanger, can increase 20% heat-exchange efficiency, and bring higher efficiency to the equipment.

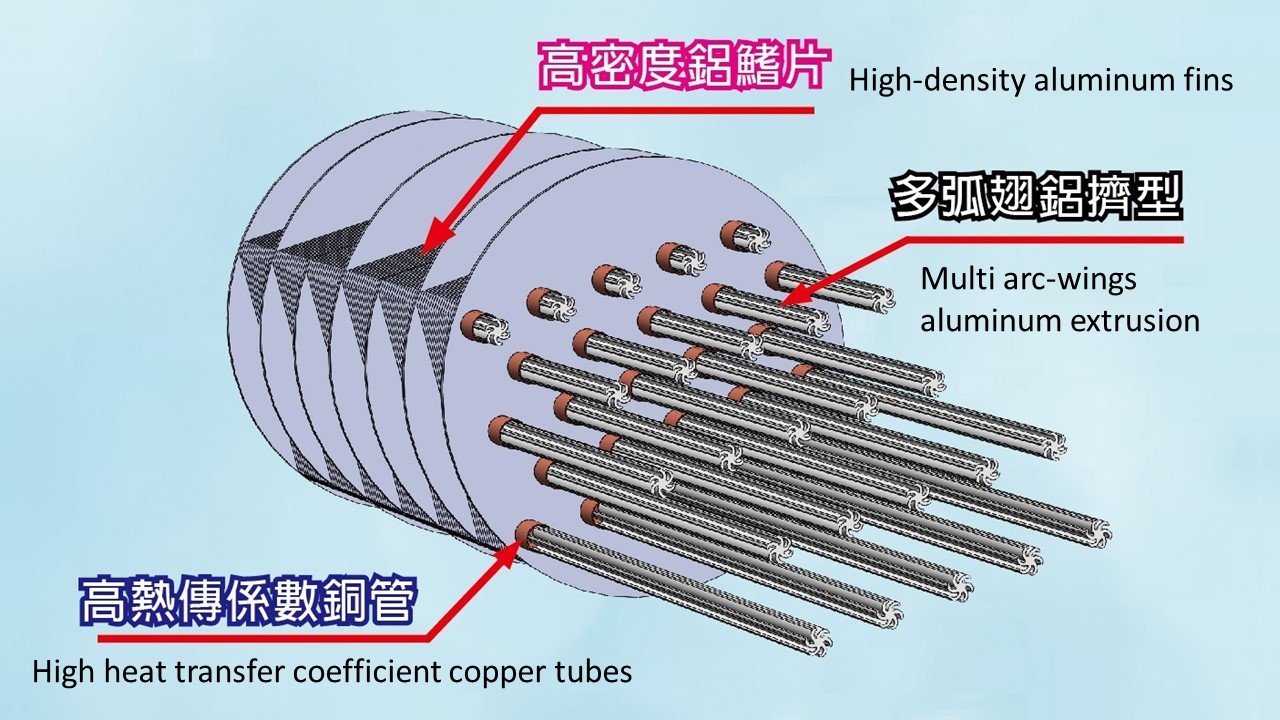

● Enhanced heat conduction fin-tube heat exchanger

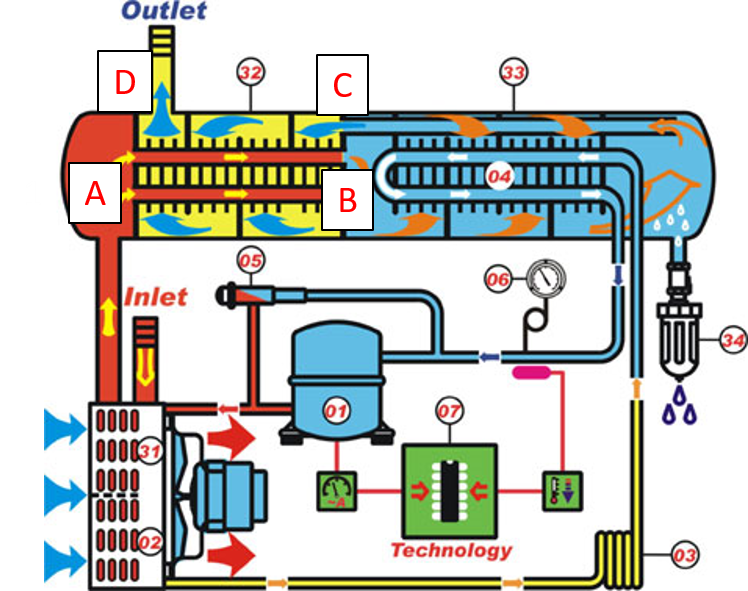

●A: Hot air Inlet B: Hot air Outlet C: Cold air Inlet D: Cold air Outlet

1) Overcome the limitation of environment temperature

First, the heat exchange efficiency becomes better, which means that the allowable inlet hot air temperature can be increased, and it can be used in a higher temperature environment. Currently, the applicable ambient temperature of our product can reach 45°C.

2) Reduce purchase and use costs

When the outlet hot air can release more heat from the heat exchanger, the temperature entering the evaporator can be lowered so that it can reduce the load of the refrigerant compressor and reduce power consumption. Additionally, when the temperature of the hot air outlet decreases, it means that the same freezing capacity can process more flow of air. The processing capacity increase more 10% than before, so that the dryers can match the modern energy-saving and high-efficiency air compressors , and there is no need to buy a larger model. In this way, it can be helpful in terms of purchase, space utilization, electricity bills, and the maintenance costs in the future.

3) Maintain the factory environment

The dry cooling air from the outlet of the evaporator, gets more temperature rise after passing through the enhanced heat exchanger, which increases the outlet temperature by 7°C compared to the previous machines. Therefore, the outlet is less dew condensation, and it can reduce corrosion to avoid pollute the factory environment.